Evaporators Manufacturers, Suppliers, Exporters in India,Maharashtra

Evaporators Manufacturers, Suppliers, Exporters in India,Maharashtra

Welcome to Thermin Energy Systems, where we provide the best Evaporators in India. Our Evaporator systems are designed to help you manage industrial wastewater effectively. We offer a Evaporator Manufacturers, Suppliers, Exporters in India,Maharashtra that are customized to meet your specific needs.

Evaporators Manufacturers, Evaporators Suppliers, Evaporators Exporters, Evaporators Manufacturers in India, Evaporators Suppliers in India, Evaporators Exporters in India, Evaporators Manufacturers in Maharashtra, Evaporators Suppliers in Maharashtra, Evaporators Exporters in Maharashtra

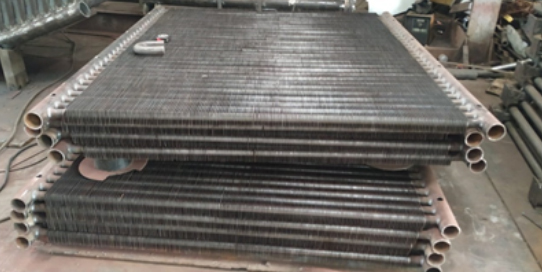

Evaporators are essential heat transfer devices used to convert a liquid into a vapor by removing the liquid's heat content. They find extensive applications in various industries for concentrating solutions, recovering valuable products, and reducing waste.

Our Evaporators Suppliers in India are dedicated to provide you with the highest quality Evaporators, service, and support. Contact us today to learn more about how we can help you manage your wastewater effectively and efficiently.

Exclusive Features

- Efficient heat transfer.

- Ability to handle a wide range of liquids.

- Versatility in design for various applications.

- Energy-efficient options available.

- Easy to scale for different production volumes.

How Evaporators work?

Evaporators generally operate by heating the liquid to its boiling point, causing it to vaporize. The vapor is then condensed and collected as a concentrated product, while the remaining liquid may be further processed or disposed of.

Types of Evaporators

- Falling Film Evaporators: These evaporators have a vertical shell and tubes design. Liquid flows down the tube walls as a thin film, allowing for efficient heat transfer. Falling film evaporators are suitable for heat-sensitive materials like fruit juices and pharmaceuticals.

- Forced Circulation Evaporators: They use a circulation pump to maintain a high liquid velocity, preventing fouling and ensuring even heating. Common in the pulp and paper industry and for brine concentration.

- Plate Evaporators: These compact evaporators have stacked plates with channels for liquid flow. They are known for their high heat transfer efficiency and are used in dairy, food, and chemical processing.

- Natural Circulation Evaporators: Operate without pumps, relying on density differences for circulation. They are cost-effective and used in applications like seawater desalination and wastewater treatment.

- Multiple-Effect Evaporators: Consist of multiple evaporator stages where the vapor from one stage serves as the heating source for the next. This design maximizes energy efficiency, commonly used in the sugar and chemical industries.

Applications

Evaporators are used in industries such as: -

- Food processing (for juice concentration and milk evaporation)

- Wastewater treatment

- Chemical processing (for solvent recovery)

- Pharmaceuticals

- Power generation (for producing high-purity water)